The Ultimate Guide to Wax/Resin Ribbons for Thermal Transfer Labels

In today’s fast-paced industries, clear, durable, and high-quality labels are crucial for efficient operations. One of the best solutions for achieving this is wax/resin ribbons for thermal transfer printing. These ribbons provide an excellent balance between cost-effectiveness and durability, making them ideal for a variety of applications. In this guide, we’ll explore what wax/resin ribbons are, their benefits, common uses, and how to choose the right one for your business.

What Are Wax/Resin Ribbons?

Wax/resin ribbons are thermal transfer ribbons made by blending wax and resin components to create a durable yet flexible print solution. When used with thermal transfer printers like the popular zebra ZD220T and ZD421, these ribbons transfer ink onto labels using heat, creating long-lasting, smudge-resistant, and semi-durable prints. They offer better resistance to moisture, chemicals, and abrasion compared to wax ribbons alone, making them suitable for demanding environments.

Benefits of Wax/Resin Ribbons

-

Enhanced Durability – Resistant to smudging, scratching, and moderate exposure to chemicals and moisture. Doesn't fade easily like direct thermal printing.

-

Superior Print Quality – Produces sharp, crisp barcodes and text for easy scanning and readability.

-

Versatility – Works on a variety of label materials, including coated paper, synthetic, and polypropylene labels.

-

Temperature & Chemical Resistance – Suitable for applications exposed to moderate heat, chemicals, and friction.

-

Longer Print Head Life – Less wear on printer heads compared to full resin ribbons, reducing maintenance costs.

-

Cost-Effective – Offers a middle-ground solution between wax and full resin ribbons, balancing performance and affordability.

Common Applications of Wax/Resin Ribbons

-

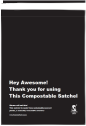

Shipping & Logistics Labels – Provides durability for handling, scanning, and transit. Better quality than direct thermal printing.

-

Retail & Inventory Management – Ensures long-lasting barcode readability for tracking and sales.

-

Pharmaceutical & Healthcare Labels – Resists moisture and mild chemicals for medical and lab applications.

-

Food & Beverage Packaging – Suitable for product labeling in moderately demanding environments.

-

Industrial & Manufacturing Labels – Withstands light exposure to chemicals, abrasion, and handling.

How to Choose the Best Wax/Resin Ribbon for Your Needs

When selecting a wax/resin ribbon, consider the following factors:

-

Label Material Compatibility – Ensure the ribbon works with your label material (paper, synthetic, etc.).

-

Print Durability Needs – Assess exposure to moisture, friction, and chemicals to choose the right balance of wax and resin.

-

Printer Compatibility – Verify that the ribbon matches your printer type (flat-head or near-edge).

-

Environmental Conditions – Consider factors such as heat, humidity, and exposure to ensure longevity.

-

Color Options – While black is the most common, some brands offer colored wax/resin ribbons for specialized applications.

Final Thoughts

Wax/resin ribbons provide a reliable and cost-effective solution for businesses that require high-quality, durable thermal transfer printing. Whether you need labels for logistics, retail, healthcare, or industrial applications, choosing the right wax/resin ribbon ensures long-lasting, scannable, and professional-looking prints.

Looking for premium wax/resin ribbons for your thermal transfer labels? Explore our selection of Thermal Transfer Labels and Wax/Resin Ribbons to find the perfect match for your labeling needs!

Always bringing you value to your eCommerce journey,

Bill Li

Director

Awesome Pack